Baking equipment can be divided into commercial and household use. Today we will talk about the commercial baking equipment needed in bakeries, including commercial baking ovens, rotary ovens, electric ovens, gas ovens, pizza ovens, etc.

- 1. The heating principle of the oven

The basic principle of an oven is that the heating tube heats the air and food inside the oven after being energized, so the oven must be preheated before baking food to reach the required temperature.

Older models of ovens use quartz tubes, but today’s newer models basically use copper tubes, which heat more evenly.

Usually there are two copper tubes at the upper and lower ends of the oven. Some ovens with particularly large volumes use W-shaped tubes, which increase the length and heating area of the heating tubes, thereby improving the heating efficiency.

The heating tube has only one power. When the required temperature is reached in the oven, the heating tube will be powered off. When the oven gradually cools down, the heating tube will be powered on again and heated again. This process is repeated to ensure a constant temperature in the oven.

Therefore, the power of the oven refers to the power during heating, but it is not powered on for heating all the time during the entire baking process.

The exposed part of the food surface is directly radiated by the heating tube, so small household ovens are very easy to burn, and the baking tray needs to be turned frequently to ensure even heating.

Tips: Gas heating tubes may bulge up occasionally during heating, which is a normal physical reaction. They will gradually return to a flat surface during cooling after the fire is turned off.

What are the hazards of electric ovens?

a. Fried foods cannot be heated in an electric oven because the remaining oil in the dough sticks will splash when exposed to high temperatures, which can easily lead to the appearance of open flames and cause safety problems.

b. The electric oven will produce some radiation when in use, which will have a certain impact on health. If you observe the electric oven light for a long time, your eyes will feel uncomfortable.

c. Do not heat ordinary plastic containers in an electric oven because the high temperature can easily cause them to deform and decompose chemicals that are harmful to health.

d. When you first start using it, you may not be able to control the heat, so it is easy to dry out the moisture or even burn it. If the food is burnt, you must throw it away. Don’t eat it out of fear of waste. Eating burnt food is not good for your health.

Notes on using the oven!

a. The temperature of the top and door of the electric oven is very high.

b. The heater of the electric oven has a certain thermal inertia. When the power is on, it takes 2-3 minutes for the heater surface to reach the normal working temperature; when the power is off, it also takes a certain amount of time to cool down. After understanding this characteristic of the oven heater, you can better control the degree of baking of food and make more delicious food.

c. Before putting food into the oven, be sure to preheat the oven.

d. Because the oven door is where the heat is dissipated, the degree of baking of the food near the oven door is always slightly weaker. In order to ensure that the food is fully and evenly baked, you can turn the baking tray halfway through the baking time and continue baking.

e. For electrical safety, the socket of the electric oven should have a good grounding wire.

f. After each use of the electric oven, wait for it to cool down, turn off the power to ensure safety, and then thoroughly clean the oven. You can wash the baking tray and baking net with water.

- 2. Hot air oven

- The hot air oven uses the heat from the upper and lower heaters in the oven to bake the food. There is a fan hidden here to circulate the hot air so that the food can be heated slowly.

- This series is mainly used for baking croissants, Danish and puff pastry products, and is suitable for baking in small spaces such as stores and laboratories.

This machine can be powered by either electric or gas, has a steam spray function, and has optional specifications of 5 to 10 trays. It can also be combined with a small fermentation box and a single-tray electric oven to save space and meet a variety of production needs.

Machine Features:

a. Suitable products: croissants, puffs, cream soups and puff pastry toppings, pizza, cheesecake, chicken legs, baked potatoes, handmade biscuits, curry cakes, moon cakes, egg yolk pastries, pineapple cakes, barbecue, etc.

b. The machine body is made of stainless steel, which is easy to clean and occupies a small area, saving machine room space.

c. Energy-saving and high heating capacity. Thickened silicone sealing strip: effectively reduce temperature loss and achieve the effect of locking temperature and controlling humidity.

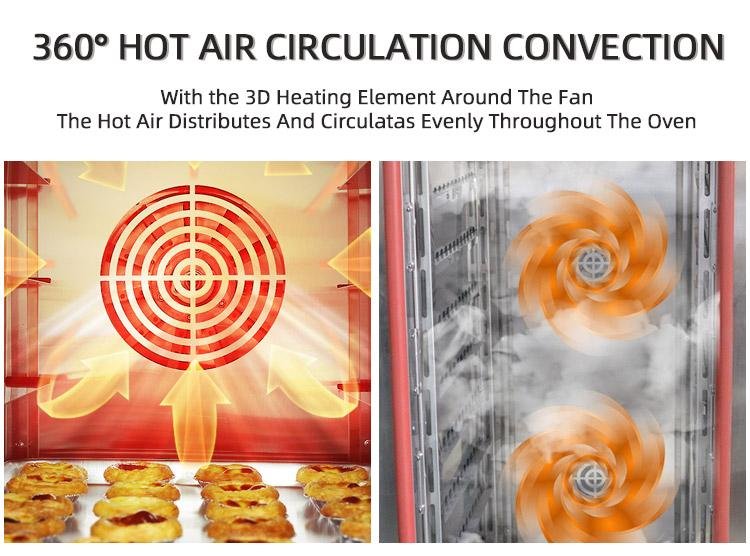

d. Special turbine impeller and special air convection design promote and improve baking efficiency. Three-dimensional 360° hot air circulation/even coloring, more uniform baking temperature, high efficiency and consistent products for multiple trays.

e. The control panel is easy to operate and has dual timers: control grilling time and steaming time separately/99 minutes timing/better control of heat.

f. Use imported electronic components: timers, AC contactors, thermostats and other electronic components are from German Schneider, Japanese Omron and Taiwan brands.

- 3. Commercial Oven

What sizes are available for commercial electric/gas ovens?

Choose an oven of appropriate size based on the store’s traffic and baking speed. The industry classifies ovens into different specifications based on the number of standard-sized [60*40 CM] baking trays and the number of oven layers.

For example, small ovens have one layer of one tray and one layer of two trays; medium-sized ovens have two layers of four trays and two layers of six trays; large ovens have three layers of six trays, three layers of nine trays and large hot air rotary ovens.

For small bakeries, one or two layers of trays and two layers of four trays are generally enough; medium-sized ovens can use two layers of four trays and three layers of six trays.

Noodle processing plants can use large three-layer nine-tray ovens, tunnel ovens, large hot air rotary ovens, etc.

Classification by heating conditions:

Gas oven: heated by liquefied gas or natural gas.

Electric oven: heated by electricity, three-phase/single-phase electricity.

Classification by product control method:

Mechanical knob control: simple operation, easy to use, suitable for all kinds of people. Computer intelligent control system: relatively accurate temperature control, also with the function of storing different menus, to achieve one-button operation of the fool-proof smart oven.

Gas Oven: Inside View

Gas oven: This is the best combustion state, the combustion tube/fire presents a straight line

Gas oven: independent temperature control for upper and lower layers, flexible adjustment of upper and lower tube temperatures, uniform baking and coloring

Commercial large capacity ovens are designed for baking enthusiasts and baking businesses with outstanding features.

Machine Features:

a. Efficient baking: Professional grade, temperature can reach 400℃, wide range temperature control, easy to handle various baking ingredients.

b. Large capacity design, suitable for commercial needs: The space inside the oven is large, and 2 baking trays can be placed on one layer (baking tray size 60*40CM), meeting the high output needs in a busy commercial environment.

c. Multi-layer design, efficient baking: Electric/gas two-layer four-tray, three-layer six-tray, three-layer nine-tray design, multi-layer baking trays can be baked at the same time, improving baking efficiency and saving time.

d. Independent upper and lower temperature control, precise control: The use of upper and lower independent temperature control technology can achieve precise temperature control according to different ingredients and baking requirements.

e. Built-in lighting for real-time observation: The equipment has built-in lighting, which allows you to observe the baking process at any time to ensure the quality and taste of the baked food.

f. Gas oven: stable voltage to ensure stable operation. Flame-out protection function, using flame-out and gas-cutting double solenoid valve safety device, safe and worry-free.

g. Commercial grade, durable and reliable: The body is made of stainless steel, and the furnace is made of imported high heat reflective aluminum plate. Made of high-quality materials, the structure is stable, durable and reliable, and can adapt to high-intensity use in commercial environments.

The oven’s commercial large-capacity design, multi-layer baking function, and 99-minute long timing function provide an efficient and convenient solution for the baking business, making it the first choice for baking enthusiasts and professionals.

- 4. Choice of dough mixer

· Multifunctional commercial mixer with stirring/beating eggs/kneading dough in one.

· Wide range of applications: The mixer has a variety of uses and can be used to mix dough, stuffing, whip eggs and cream, etc. It is an indispensable equipment for making pastry products. The Mailekitchen mixer is produced using strict production standard processes and can provide customers with efficient and stable production support.

Advantages and disadvantages of home kitchen machines

Advantages: small footprint, low power consumption, easy to use and easy to clean.

Disadvantages: Small capacity, not suitable for mass production in stores. Due to the large difference in power and speed from commercial equipment, the dough is likely to be less smooth and fused, and is easily damaged.

Recommendation: Suitable for beginners to play with at home, not suitable for commercial use.

Advantages and disadvantages of single-action mixers

Advantages: It can stir fillings/beat eggs (cream)/knead dough in one. It is cheap (relative to double action), the barrel can be removed for cleaning, and it is easy to operate.

Disadvantages: A bit noisy. Since the dough bowl is stuck on the machine, it is easy to make a banging sound when stirring.

Recommendation: Generally, suitable for beginners or shops with small investments (noodle shops/bakery shops).

Recommended capacity for small and medium-sized shops: Choose a machine with a volume of 20-30L.

Advantages and disadvantages of double action dough mixer

Advantages: large capacity, quiet, and easy to form dough.

Disadvantages: The price is relatively higher, and the noodle bowl cannot be removed for cleaning (there are also removable ones, but they are too expensive).

Recommendation: High. Many professional baking chefs choose double-action dough mixers, which are suitable for dough making in all kinds of shops.

It is recommended that small and medium-sized stores purchase 15-20L volume machines, which can meet most needs. Medium and large stores can choose 30-40L volume machines. Factories or central kitchens can choose 80-130L super-large assembly line machines.

Single Action Mixer:

The spiral dough mixer can easily complete the dough kneading work, and it is powerful, efficient and fast in producing film, which is not inferior to the effect of manual kneading. It is more convenient and worry-free. It can provide dough for the production of various delicacies. Multiple speed adjustment, according to different materials, the speed is adjusted to effectively knead dough, mix stuffing and whip.

- 5. Proofing Box

Problems that may occur during the final fermentation process

· The bread has risen before the time limit. Can I stop the fermentation?

It is best not to stop proofing immediately, as it is sometimes difficult to tell if the bread has risen enough, and insufficient proofing will result in the bread not expanding properly when baked. Unless the bread looks like it is collapsing, it is best to let it rise for the minimum time required by the recipe.

· When the dough was finally proofed, it didn’t rise but stretched out. What happened?

There are two possibilities. One is that the dough is not kneaded properly and has not formed enough gluten to wrap the air produced by yeast fermentation and support the structure of the bread.

Another possibility is that it has been over-fermented. You can reshape the bread and then let it ferment, but the fermentation time can be halved. When the dough looks soft but not collapsed, you can put it in the oven.

· What should I do if the dough sticks together during the final rise?

You can use a knife to cut them apart, and be careful to leave enough space between the bread next time.

· What should I do if I forget to wrap the dough before it rises, causing the surface to become dry and cracked?

Proofing

a. Final proofing softens the gluten, makes the dough more extensible, and adds flavor to the finished product.

b. Depending on the type of finished product and other factors, the humidity, temperature and time of the final proofing need to be controlled well. Generally, the temperature is 30℃-35℃, the humidity is 75%, and the time is 30-90 minutes.

c. You can use touch, observe the size of bubbles, dough expansion rate and other methods to determine whether the final proofing is complete.

d. Gently press the dough. If the indentation does not bounce back, it is over-fermented. If the indentation bounces back quickly, it is under-fermented.

· What are the specific categories of wake-up boxes?

There are proofing boxes, refrigerated proofing boxes, frozen proofing boxes and proofing rooms. There are many specifications of proofing boxes, 16 trays, 32 trays, smart version, ordinary version, refrigerated version, spray type. Choose according to your needs and store environment.

A proofing box is a must-have for bakers. It is suitable for shops that bake and sell freshly-baked goods. It helps bakers set the dough proofing time one day in advance and improve bread production efficiency.

a. Automatic water filling function, no need for manual water filling.

b. Temperature/humidity dual control makes the fermentation softer and more elastic. The internal micro fan circulates hot and humid air for more uniform fermentation.

c. Temperature/humidity dual control makes the fermentation softer and more elastic. The internal micro fan circulates hot and humid air for more uniform fermentation.

d. The inside and outside of the box are made of stainless steel, which is durable, clean and hygienic. The tempered glass window allows you to see the fermentation process clearly.

- 6. Other baking equipment

Mailekitchen manufactures and sells tunnel ovens, rotary ovens, electric ovens, gas ovens, pizza ovens, proofing boxes, baking equipment, and also produces and sells a series of baking equipment such as dough mixers, egg beaters, block dividers, forming machines, puff pastry machines, etc.

Some of our products have passed the EU CE, UL, and IS09001 quality system certifications, and we are committed to providing professional and complete baking production equipment to bakers around the world.