CUSTOM BAKERY OVEN

Get started on our fully customizable bakery oven with no minimum quantity.

Low Minimum Qty

Quality and cost control

Factory Direct

24 Hours Online

OEM/ODM

Classic electric oven

Classic gas oven

Standard electric oven

Standard gas oven

Fashion type electric oven

Fashion type gas oven

ROTARY OVEN

Dual Fuel 2 In 1 Model Can Be Choose

12 16 26 32 64 trays

Electric,Gas and Diesel type to match clients’ demand. We also can do 2 in 1 function for Electric & Gas and Electric & Diesel rotary oven.

5 8 10 12 trays

Equip with rotary fan hot air circulation distributes heat evenly, Baked food color more brightly.

Standard is micro-computer panel,can optional change to digital panel.

Equip with steam spray function,Suitable for a variety of food baking.

Be absorbed in every details

Stainless Steel Durable Structure Design, The Oven Boby Adopt Stainless Steel Which Are Temperature Resistance, Corrosive Resistance,High Strength, Effectively Prevent Deformation At High Temperature.

Advanced Far Infrared Heating Tubes, Far infrared heating tubes to heat the food rapidly and uniformly. Heat Resistant Doorknob, Black Plastic doorknob Anti-scald and easy open Easy Operation And Maintenance, The Door opend at an Angle of 180 degrees To facilitate push Trays into the oven

Waterproof And Dustproof Cooling Holes, Circulation Ventilation Design To Avoid Over temperature And Ensure Long Life Time. Visual Double Glass Window, Double Tempered Glass Windows Design Prevents Heat From Getting Out.

Built-in Temperature Probe, Equipped Constant Temperature Automatically Accurate Temperature Control To Prevent Temperature Difference. Safety Protection Device, Safety Over-Temperature Protection Device, More Safer And Secure. Built-in Lighting, Built-in explosion-proof light The baking processes are very easy to observe.

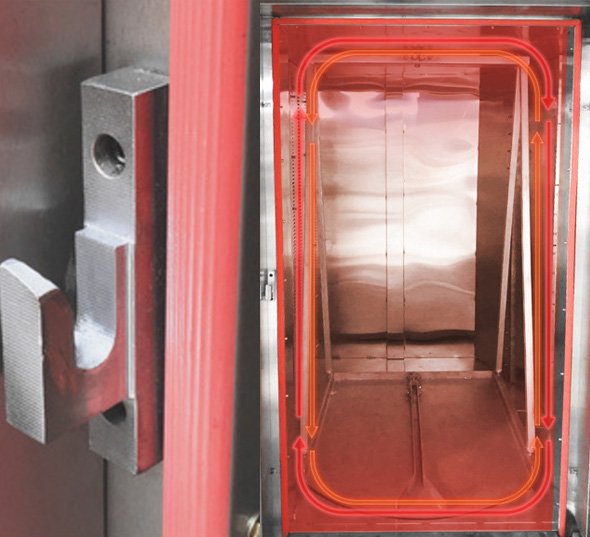

HEAT REFLECTION DOUBLE TEMPERED GLASS

Heat Insulation Performance & High-Temperature Resistance

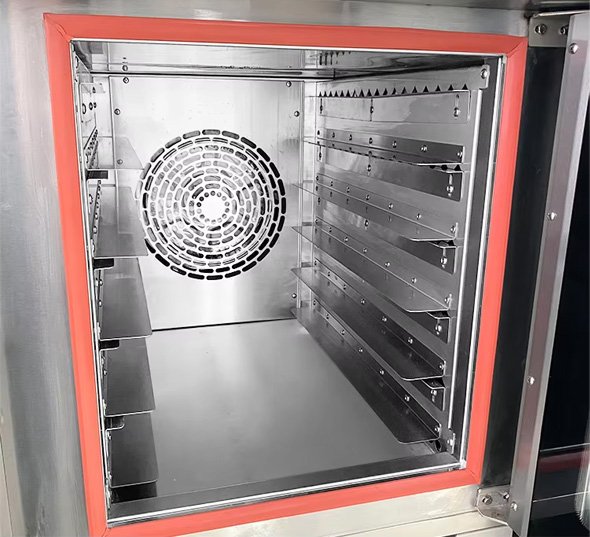

360°HOT AIR CIRCULATION CONVECTION

With the 3D Heating Element Around The FanThe Hot Air Distributes And Circulatas EnvenlyThrouohout The Oven

BETTER FOR BAKING MULTIPLE TRAYS AT ONCE

Perfect And Smooth Baking Result On Each Layer Insulation Door Sealing Strip For Stable Temperature

STEAM INJECTION FUNCTION

Maintain The Humidity For Better Taste Of The Food Perfect For Baking Artisan Bread

Sealing property, The heat resistance silicone gasket helps sealed the door. 360 Degrees Rotary Heating, Heating Evenly

Adjustable hot wind outlet

Reasonable Hot Air Circulation Design Ensure uniformity of baking. Adjustable vent suitable for different products 360 DEGREE HEAT CIRCULATION DESIGN

Built-in Lighting Check the baking inside the oven at any time. Perspective windows and doors, Double-layer tempered glass design prevents burns and easy to clean.

Rotary bottom can be rotated, which can bear large weight and increase the service life of the rotating motor. It's easier to operate for baker. Stainless Steel Strong Frame

Multiple control system

A variety of control systems to meet different baking needs

Microcomputer control panel

Easy to operate luxury and high-grade fashionable appearance accurate temperature adjustment

Fashion exhaust valve, Simple appearance convenientoperation durable and safer. Handle design, Beautiful and fashionable appearancehigh-grade material smore safe andreliable operation.

Heating tube

No redness, uniform and stableheating, safe and reliable, so thatthe baking quality is superior

Silicone sealing strip

Good sealing performance, high temperature resistance,corrosion resistance, anti-aging, shockproof and waterproof,heat preservation effect is more significant.

European style door

Panoramic high temperature resistant tem-pered glass makes it easier to observe bakedproducts, the glass is opened upside down,does not take up space, and is convenient totake out the product

Make Your Own Bakery Oven

Step 01 : Select Products Categories

- Deck Ovens

- Convection Ovens

- Rotary Ovens

- Combination Ovens

Step 02: Select Energy Sources

- Deck oven:Electric/Gas/Electric & Gas 2 in 1

- Convection oven:Electric/Gas

- Rotary oven:Electric/Gas/Diesel

Step 03: Select Layers

Deck oven

1 deck 1 tray

1 deck 2 trays

1 deck 3 trays

2 decks 2 trays

2 decks 4 trays

2 decks 6 trays

3 decks 3 trays

3 decks 6 trays

3 decks 9 trays

3 decks 12 trays

Convection oven

5 tray

8 tray

10 tray

12 tray

Rotary oven

12 tray

16 tray

26 tray

32 tray

64 tray

Step 04: Select Panel

Knob

Digital(Standard)

Micro-Computer

Steam Function Memory Mode

Step 05: Select Function

Optional item:Stone,Steam,Seal can be choose

Step 06: Select Handle

Frequently Asked Questions For Bakery Oven

| Feature | Rack Oven | Deck Oven |

|---|---|---|

| Design | Multiple racks for trays, often taller and wider | Individual baking decks, shorter height |

| Baking Method | Convection, with air circulation and steam injection | Direct heat, often with steam options |

| Baking Capacity | Can hold many trays at once (high volume) | Limited to number of decks (each deck bakes separately) |

| Product Specialty | Versatile for many products | Best for artisanal bread and pizza |

| Heat Retention | More variable thermal mass | Excellent due to stone/ceramic decks |

| Flexibility | Can adjust temperatures for different racks | Each deck can have its own temperature setting |

| Feature | Bakery Oven | Pizza Oven |

|---|---|---|

| Purpose | Versatile for a range of baked goods | Specifically for baking pizzas |

| Types | Convection, deck, rack, combination ovens | Wood-fired, gas, electric, conveyor ovens |

| Temperature Range | 350°F to 500°F (175°C to 260°C) | 500°F to 800°F (260°C to 427°C) or more |

| Baking Time | Varies depending on the product | Usually 90 seconds to 3 minutes |

| Humidity Control | Often includes steam or humidity control | Generally no humidity control |

| Heat Distribution | Even, suitable for multiple products at once | High direct heat, ideal for fast, crispy crusts |

A rack oven is a versatile piece of baking equipment designed to accommodate a large volume of baked goods simultaneously. It is commonly used in commercial bakeries due to its ability to evenly bake a variety of items.

Baked Goods Suitable for Rack Ovens

Bread:

Artisan bread, loaves, rolls, baguettes, and specialty breads. The even heat distribution and steam capabilities of rack ovens make them ideal for developing a good crust on bread.

Pastries:

Croissants, Danish pastries, puff pastries, and turnovers. The convection feature helps achieve flaky layers.

Cookies:

Drop cookies, cut-out cookies, and sheet cookies. Multiple trays can be baked simultaneously, making it efficient for batch production.

Cakes and Muffins:

Layer cakes, sheet cakes, cupcakes, and muffins. Rack ovens provide consistent baking temperatures, which is crucial for maintaining moist cakes.

Pizzas:

While pizza is often associated with specific pizza ovens, rack ovens can also be used for baking pizzas, especially if steam injection is available.

Biscotti and Crackers:

Biscotti and various types of crackers can be baked evenly due to the controlled environment.

Scones and Biscuits:

These can benefit from the even browning and consistent heat during baking.

A rack oven is an excellent tool for commercial bakeries, allowing for the efficient and consistent baking of a wide variety of products. By understanding its capabilities and adjusting for specific recipes and products, you can achieve excellent results across different types of baked goods.

*The biggest feature of the convection oven is that there is only one kind of temperature in the body, 60 kinds of programs can be

stored, so that each baking can achieve the best state.

*And the heat of the heating tube is transmitted through the motor fan to each place of the inner.

*Compared to other baking oven, it saves power, space, time. The liner height is 11cm.

*The distance can be fine-tuned for more uniform heat transfer. With steam device, can dry fruit.

*Suitable for kinds of products, especially such good for moon cake, toast bread, baguette, biscuit, crispy buns etc.Hot air circulation inside the oven, good baking effect with consistently even.Advanced electronic, auto timer, auto temperature system.

*A convection oven has a fan and exhaust system. The fan circulates the hot air inside the oven cavity. This forced air circulation distributes heat more evenly around the food.

Convection ovens generally cook food faster than traditional ovens. The circulating air allows for more efficient heat transfer to the food.

It is excellent for a wide range of cooking tasks such as baking, roasting, and dehydrating.

Convection ovens come in various sizes, from small counter top models to large wall – mounted or freestanding units.

*A rack oven typically uses a combination of radiant heat from the top and bottom elements and natural convection. There is no forced – air fan like in a convection oven. The heat rises from the bottom and radiates from the top, and the air moves around the food in a more natural way due to temperature differences.

Rack ovens are often preferred for baking large quantities of items such as bread loaves or trays of buns. The racks can be adjusted to different heights to accommodate different sizes of baking pans.

Rack ovens are usually larger and designed with the intention of baking multiple items at once. They are commonly used in commercial bakeries or food service establishments. The racks are usually sturdy and can hold heavy baking trays. Some rack ovens have doors that open wide to allow for easy loading and unloading of the racks, which is convenient when dealing with a large number of items.

You can bake almost anything in them! Pastry, panettone, tarts, pies, bread, cookies, cakes, meat, even some styles of pizza. Suitable for hotels, bakeries, various canteens, western restaurants, cafes, tea shops, cake shops, private baking, etc.

Heating Method

- Electric Deck Oven: Heats up by using electric heating elements, such as heating coils or heating tubes. When electricity passes through these elements, they generate heat to bake food.

- Gas Deck Oven: Burns natural gas or propane gas to produce heat. The gas is ignited by a burner, and the flame heats the interior of the oven.

Temperature Control

- Electric Deck Oven: Generally offers more precise temperature control. It can maintain a relatively stable temperature throughout the baking process, which is beneficial for baking delicate pastries or items that require strict temperature control, such as some specialty breads and cakes.

- Gas Deck Oven: Provides more immediate heat adjustment. Chefs can quickly change the temperature by adjusting the gas flow and burner intensity, allowing for faster responses to sudden changes in baking needs, like when browning the top of a dish quickly.

Heat Distribution

- Electric Deck Oven: May have hot spots in some models, which means that the heat may not be evenly distributed throughout the oven cavity, potentially resulting in uneven baking. However, some advanced electric ovens come with features like convection fans to improve heat circulation and distribution.

- Gas Deck Oven: Typically provides more even heat distribution, ensuring that food is cooked uniformly. The natural convection caused by the heat rising from the burners helps to create a more consistent baking environment, which is advantageous for baking large items or multiple trays of food simultaneously.

Operating Costs

- Electric Deck Oven: Generally has a higher operating cost, especially during peak electricity usage times. The cost of electricity can add up, especially if the oven is used frequently or for long periods.

- Gas Deck Oven: Usually more cost-effective to operate, especially in areas where natural gas prices are relatively low. Gas is often a cheaper fuel source compared to electricity, resulting in lower long-term operating costs.

Maintenance and Cleaning

- Electric Deck Oven: Easier to clean and maintain. There are no burners to clean, and there is no need for regular gas line inspections or maintenance. The interior surfaces are generally smooth and can be easily wiped down.

- Gas Deck Oven: Requires more frequent maintenance. Burners need to be cleaned regularly to ensure proper combustion and prevent clogging. Gas lines also need to be inspected periodically for leaks and other safety issues.

Safety

- Electric Deck Oven: Eliminates the risk of gas leaks, providing a safer working environment. There is no open flame, reducing the potential for fire hazards. Additionally, electric ovens usually have features like automatic shut-off and overheat protection.

- Gas Deck Oven: As long as proper safety precautions are taken, such as regular inspections of gas lines and proper ventilation, gas ovens can be used safely. However, the presence of gas and an open flame requires more attention to safety to prevent gas leaks, explosions, and fires.

Speed of Heating

- Electric Deck Oven: Usually has a slower heating speed compared to gas ovens. It may take longer to preheat to the desired temperature, especially if the oven has a large capacity.

- Gas Deck Oven: Heats up more quickly due to the direct heating provided by the gas flame. This can be a significant advantage when time is of the essence, such as in a busy commercial kitchen where quick turnaround is required.